- Disponível nas versões para microbiologia e cultura celular

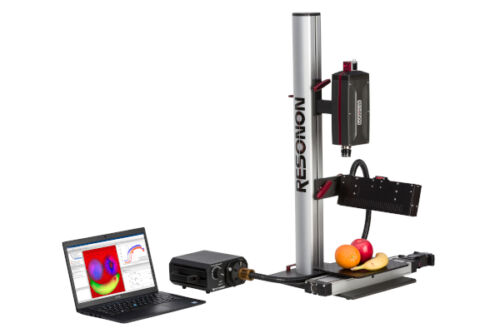

- Sistema de controle de biorreator de bancada

- Excelente custo/benefício

- Motor montado na embarcação com sistema de travamento exclusivo

- Sistema intuitivo de medição e controle com acionamento motorizado embutido

- Recipientes totalmente autoclaváveis com defletores removíveis e bobina de resfriamento

Especificações Técnicas

- Recipientes – Bacteriológico | Cultura de células | Agitação por ar (Air lift)

- Volume de trabalho (litros): 2, 5, 10 | 2, 5, 10 | 8

- Volume total (litros): 2,7, 6,4, 12,4 | 2,6, 6,3, 12,3 | 10

- Portas de 6,3 mm: 6-7 | 8-9 | 6

- Portas de 12 mm: 5-7 | 5-7 | 7

- Portas de 25 mm: 4 (Air Lift)

- Agitação

- Faixa de velocidade (rpm): 0-1000 | 0-800 | N/A

- Opção alta velocidade (rpm): N/A | 0-200 | N/A

- Controle de temperatura

- Aquecimento: Sensor PT100 para medição da temperatura do recipiente, aquecimento com baixa voltagem (24 V) com sistema circular

- Refrigeração: Serpentina/palhetas integradas / Trocador de calor tipo “Cold Finger” opcional

- Faixa: 5°C acima da temperatura da água de refrigeração até 50°C

- Controle de pH

- Bacteriológico – utiliza eletrodo de pH autoclavável, controle pr adição de ácido ou base por duas bombas

- peristálticas Watson Marlow

- Cultura de células – utiliza eletrodo de pH autoclavável, controle por fluxo de gás CO2

- Faixa: 0-14 pH com calibração na tela e monitoramento por eletrodo

- Controle de OD (Oxigênio dissolvido)

- Bacteriológico – utiliza eletrodo polarográfico autoclavável de OD, controlado tanto pela velocidade de agitação,

- fluxo de ar ou combinação de ambos.

- Cultura de células – utiliza controle de fluxo de gás, com ar, O2, N2 ou CO2

- Air Lift – por fluxo de ar

- Faixa: 0-120% com calibração na tela e monitoramento por eletrodo

- Controle de espuma: utiliza tanto sonda de condutividade ou timer com com sensibilidade variável.

- Bomba de alimentação: totalmente ajustável, utilizando timers liga/des. Fluxo máximo de 6,4 ml/min

- Energia: 230 V, 50 Hz ou 115 V, 60 Hz – normalmente 1 kW

- Programa: software SCADA capaz de controlar e coletar dados de até 8 fermentadores com conexões RS232 ou RS485.